Application of anti-static silicone for transfer printing

Anti-static silicone rubber is used for surface printing of plastic, porcelain, ceramic, pvc and hardware products. It has good resistance to wearing, no distortion, no leakage and good ink transfer property.

Charateristic of anti-static silicone for transfer printing

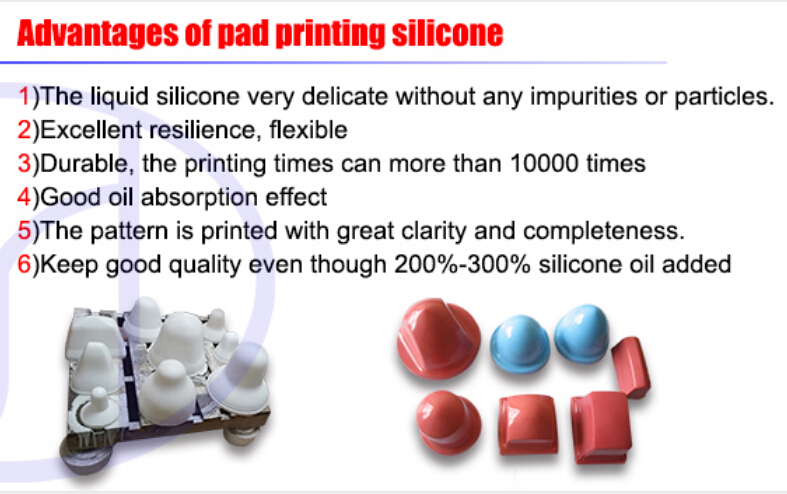

1. The liquid silicone very delicate without any impurities or particles

2. Excellent resilience, flexible

3. Durable, the printing times can be more than 500000 times

4. Good oil absorption effect

5. The pattern is printed with great clarity and completeness

6. Keep good quality even though 200%-300% silicone oil added.

Features of anti-static silicone for transfer printing

High print times and abrasion resistance Without any inpurities With good printing effects Permanent and durable.

Operation instructions of anti-static silicone for transfer printing

1.)Firstly, prepare all the necessary tools ,like the pad mold, a cup used for mixing, a glass stick, a wooden board with several holds and the size should be the same as the pad

2)Adjust the ratio between the silicon rubber and silicon oil according to the customer’s requirement. If customers want to print large patterns, soft silicon pad is needed and more silicon oil should be added. Otherwise, hard silicone pad is needed, less or none silicone oil should be added. In general, the silicone pad with 15-25 shore A is most suitable. More silicone oil added, the silicone pad is more soft,which will lead to less printing times , the rising of costs and waste of raw materials. For the molecular of silicone will be destroyed by silicone oil , which leads to wear-resisting, solvent resistance and easy aging

3)weight the silicon and catalyst exactly based on the ratio of 100:2. Pls kindly note that the amount of catalyst should be the 2% of the total weight of silicone and silicone oil.

4)weight the silicon and catalyst exactly based on the ratio of 100:2. Pls kindly note that the amount of catalyst should be the 2% of the total weight of silicone and silicone oil.

5)Vacuum pumping to de-air. The time is around 3-5 mins.

6)4-6 hours later, the silicone is cured completely. Get silicone pad from the mold and a printing pad is completed.

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号